Transducer – description

The cylindrical transducer allows the sonar beam to provide a full 360 degrees coverage of the water volume.

The transducer converts the electric energy generated by the transmitter circuitry to physical vibrations. These vibrations alter the water pressure, and create an acoustic pulse that is sent into the water. The acoustic signal is transmitted as a beam. The duration of the acoustic pulse, as well as its frequency and shape, are controlled by the system software. The direction and opening angle of the beam is controlled by the transmitter circuitry and the physical properties of the transducer. After the transmission, the transducer works as a "microphone". It converts the water pressure created by the acoustic echoes to electric energy. These weak echo signals are sent to the amplifiers in the receiver circuitry.

The transducer is covered with a thick red or black protective coating made of a special plastic type. The protective coating is a vital part of the transducer. It is very important that neither this coating nor the internal parts of the transducer are damaged during the handling, installation or cleaning. Any holes and/or scratches in the transducer surface will allow water to penetrate the transducer. If a leak occurs, the transducer must be replaced.

The transducer converts the electric energy generated by the transmitter circuitry to physical vibrations. These vibrations alter the water pressure, and create an acoustic pulse that is sent into the water. The acoustic signal is transmitted as a beam. The duration of the acoustic pulse, as well as its frequency and shape, are controlled by the system software. The direction and opening angle of the beam is controlled by the transmitter circuitry and the physical properties of the transducer. After the transmission, the transducer works as a "microphone". It converts the water pressure created by the acoustic echoes to electric energy. These weak echo signals are sent to the amplifiers in the receiver circuitry.

The transducer is covered with a thick red or black protective coating made of a special plastic type.The protective coating is a vital part of the transducer. It is very important that neither this coating nor the internal parts of the transducer are damaged during the handling, installation or cleaning. Any holes and/or scratches in the transducer surface will allow water to penetrate the transducer. If a leak occurs, the transducer must be replaced.

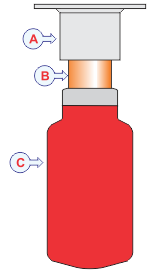

- Lower part of shaft sleeve

- Lower part of transducer shaft

- Transducer with the protective coating

The transducer is mounted at the bottom end of the hull unit’s transducer shaft. This allows the transducer to be lowered into the water for operational use, and retracted for protection when the ST90 system is turned off. By lowering the transducer into the water, you may also be able to reduce the noise created by the laminar flow of water along the hull.

The transducer is large and heavy. It contains 384 individual elements.

Rules for transducer handling

A transducer must always be handled as a delicate instrument. Incorrect actions may damage the transducer beyond repair. Observe these transducer handling rules:

- Do not activate the transducer when it is out of the water.

- Do not handle the transducer roughly. Avoid impacts.

- Do not expose the transducer to direct sunlight or excessive heat.

- Do not use high-pressure water, sandblasting, metal tools or strong solvents to clean the transducer.

- Do not damage the outer protective skin of the transducer.

- Do not damage the outer protective skin of the transducer face.

- Do not step on the transducer cables.

- Do not damage the transducer cables. Avoid exposure to sharp objects.