Accessing the installation trunk by lowering the transducer

To do a visual inspection of the inside surface of the installation trunk you need access.Access is also required to inspect and or replace the sacrificial anodes.This access can be achieved by lowering the transducer as far as it goes.

The vessel is in dry dock. The ST90 system is turned off. The shipyard must provide all necessary tools and manpower.

You need a suitable screwdriver or a large coin to open the Motor Control Unit cabinet. You also need a 4 mm Allen key.

Two persons are needed to do the task.

- One person must stay in the sonar room to operate the hull unit.

- One person must stay in the dry dock, under the hull, to make sure that the transducer is not lowered too far down.

Proper oral communication must exist between the sonar room and the dry dock personnel.

On larger hull units, the hoist motor is provided with a motor brake. The motor brake must be released before the transducer is manually lowered or hoisted.

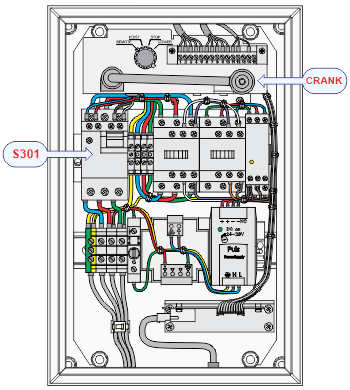

When not in use, the hand crank must always be placed inside the Motor Control Unit. When removed from its storage position the hand crank releases a safety switch which disables hull unit operation.

The transducer is covered with a thick red or black protective coating made of a special plastic type. The protective coating is a vital part of the transducer. It is very important that neither this coating nor the internal parts of the transducer are damaged during the handling, installation or cleaning. Any holes and/or scratches in the transducer surface will allow water to penetrate the transducer. If a leak occurs, the transducer must be replaced.

Procedure

- Make sure that the ST90 system is turned off.

- Make sure that you have sufficient height between the hull and the dry dock floor.

- Lowering the transducer:

- Use a spanner to open

the door on the Motor Control Unit.Warning:

High voltages are used. This equipment must be serviced only by qualified personnel familiar with high-voltage equipment and the potential hazards involved. Failure to observe this precaution could result in bodily injury. You may be exposed to electric shock. Read and understand the applicable first aid instructions related to electric shock.

- Locate the Motor Protecting Switch (S301).

- Deactivate the Motor Protecting Switch (S301) by pressing the operating handle to OFF.

- Locate the hand crank inside the Motor Control Unit.

- Remove the hand crank from its storage position.

- Remove the plastic plug on the top cover of the hull unit.

- Mount the hand crank onto the stub shaft through the hole in the top cover.

- Locate the brake release screw on the motor.

- Use an 4 mm Allen key to rotate the screw clockwise until the motor brake is released.

- Turn the crank until the transducer is fully lowered.

- Use a spanner to open

the door on the Motor Control Unit.

- Hoisting the transducer:

- Mount the hand crank onto the stub shaft through the hole in the top cover.

- Turn the crank until the transducer is fully retracted.

- Loosen the brake release screw to engage the motor brake.

- Check with the hand crank to ensure that the motor brake is engaged.

- Remove the hand crank from the stub shaft, and mount it in its storage position in the Motor Control Unit.

- Activate the Motor Protecting Switch (S301) by pressing the operating handle to ON.

- Make sure that the Hoist/Lower Switch is set to REMOTE.Note:

For normal operation from the Operating Panel, the switch must be set to REMOTE.

- Close the door on the Motor Control Unit.